What Are Traditional Bulletproof Vests Made From?

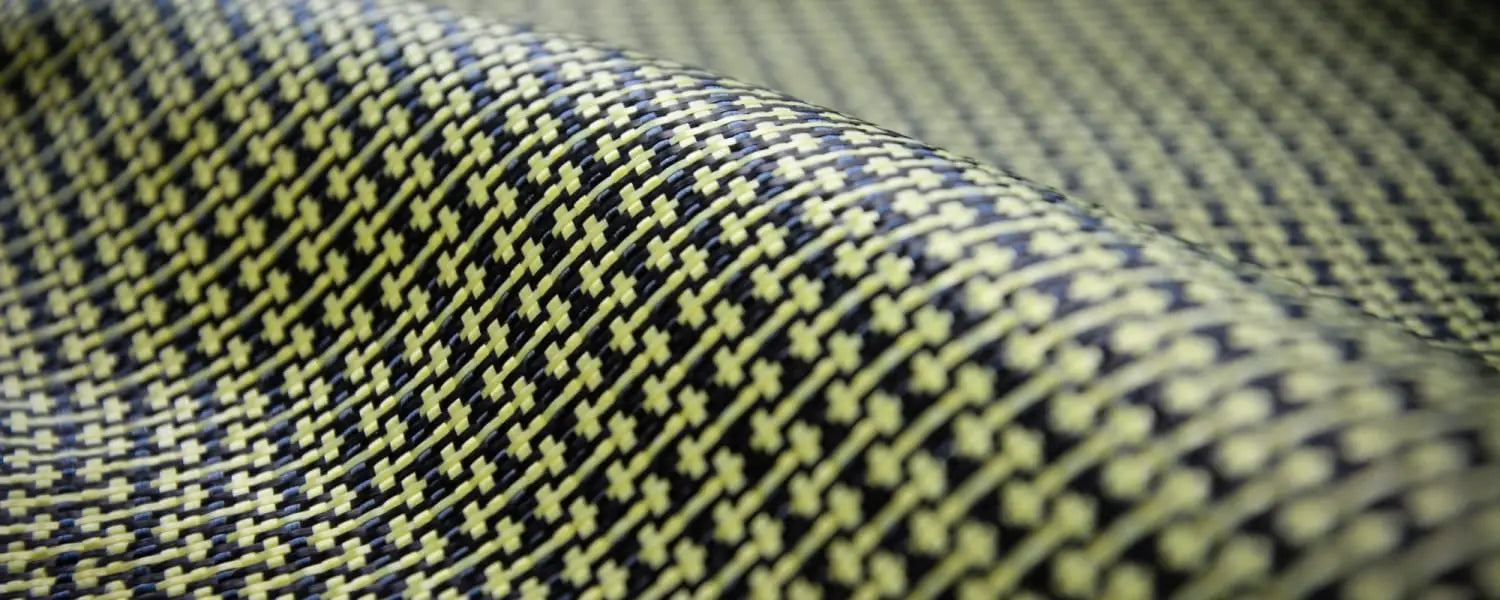

Bulletproof vests are made from a variety of high tensile strength fibers. What is inside of a bulletproof vest depends on the manufacturer. Manufacturers of bulletproof vests use various high strength materials, such as aramid fibers, carbon nanotubes, polyethylene and graphene microfibers. These fibers are combined into layers to increase the ballistic properties. The polyethylene used in bulletproof vests is an Ultra High Molecular Weight Polyethylene (UHMWPE). UHMWPE was originally developed to be used in replacing steel belts in tires. This makes it a great material for bulletproof vests due to its strength and hydrophobic properties. We’ve come a long way since the first bulletproof vests were made of silk. Vests made with UHMWPE are not only waterproof but offer cost effective ballistic protection.

There are 5 levels of ballistic protection recognized by the National Institute of Justice. The levels are IIA, II, IIIA, III, and IV. The lowest level of protection is a level IIA. As the level of protection a vest provides increases up to level IV so will the quality of the materials, the weight, and the cost of bulletproof vests.

Level IIIA is currently the highest level of protection available in a soft body armor product. Soft body armor is often preferred as it allows for a wider range of motion and weighs considerably less than hard armor plates. This level of bulletproof vest is able to provide protection from virtually any handgun round.

Higher levels of protection such as III and IV are achieved with hard armor plates. Common materials for these armor plates include steel, ceramic, and UHMWPE polyethylene.